Are the SmartAC.com sensors enough for diagnostics & repair work?

Are the SmartAC.com sensors enough for diagnostics & repair work?

The first thing you may ask yourself when looking at a product like SmartAC.com is “Can you really determine if a system is operating properly and furthermore predict a breakdown with such a simple set of sensors?”

The short answer is yes, and that in my opinion is the genius behind what SmartAC.com is doing. At its fundamental level, work measurement focuses on determining the length of time necessary to complete a unit of the task. In the world of HVAC, that work is typically reducing the temperature of a conditioned space while simultaneously reducing the grains of moisture (absolute humidity) in the room to a comfortable dew point temperature (50-55 degrees dew point temperature is typical). The work is executed in a period reasonable for the heat gain due to outdoor air temperature.

The critical element when monitoring the work is to have a good starting place. There is much less value in monitoring a poorly operating system. In fact, it has about as much value as installing a programmable thermostat on a poorly operating system that simply ends up wasting energy more efficiently. System monitoring without having a good starting place will almost assuredly result in a call back or secondary truck roll that is unlikely to generate revenue. Afterall, the problem should have been identified at the time of initial service. But as industry studies have shown time after time that over 70% of systems have at least one fault. That means most technicians are not finding the faults and leaving the system operating that way.

Starting the process by using measureQuick (A fault-finding diagnostic tool) to commission the system, and following the #betterhvac framework (getting it set up with correct refrigerant charge and system airflow, identifying and correcting problems like return air duct leakage, undersized filters, or a dirty condenser) will create billable opportunities upfront as well as curtail a callback or need for service in the immediate future. Continual monitoring with smartAC.com will ensure that the system continues to operate in that manner until it degrades to the point service is actually needed due to a detected change in the being done. Maintaining the system with measureQuick and returning it to its measured benchmark ensures that it is operating as well after service as it did when it was first commissioned.

Starting the process by using measureQuick (A fault-finding diagnostic tool) to commission the system, and following the #betterhvac framework (getting it set up with correct refrigerant charge and system airflow, identifying and correcting problems like return air duct leakage, undersized filters, or a dirty condenser) will create billable opportunities upfront as well as curtail a callback or need for service in the immediate future. Continual monitoring with smartAC.com will ensure that the system continues to operate in that manner until it degrades to the point service is actually needed due to a detected change in the being done. Maintaining the system with measureQuick and returning it to its measured benchmark ensures that it is operating as well after service as it did when it was first commissioned.

So, what is SmartAC.com measuring?

1. Excessive or short system cycle times

The time required to do the work is dependent upon the load and the rate of load increase in the house. In other words when it is hotter and or more humid outside your system will run longer to satisfy the load requirements. Ideally as we approach the design temperature the run times will approach 100%.

The primary work we are performing is controlled by the thermostat (that only measures temperature) starting a cooling cycle by detecting an increase in temperature in the conditioned space, the secondary work or conversely simply a byproduct of temperature reductions is the removal of moisture if and only if the evaporator coil falls below the dewpoint temperature.

So, at the end of the day, tracking the outdoor air temperature, we should be able to have a reasonable expectation of how long a system would have to run to satisfy the thermostat.

2. Temperature Difference

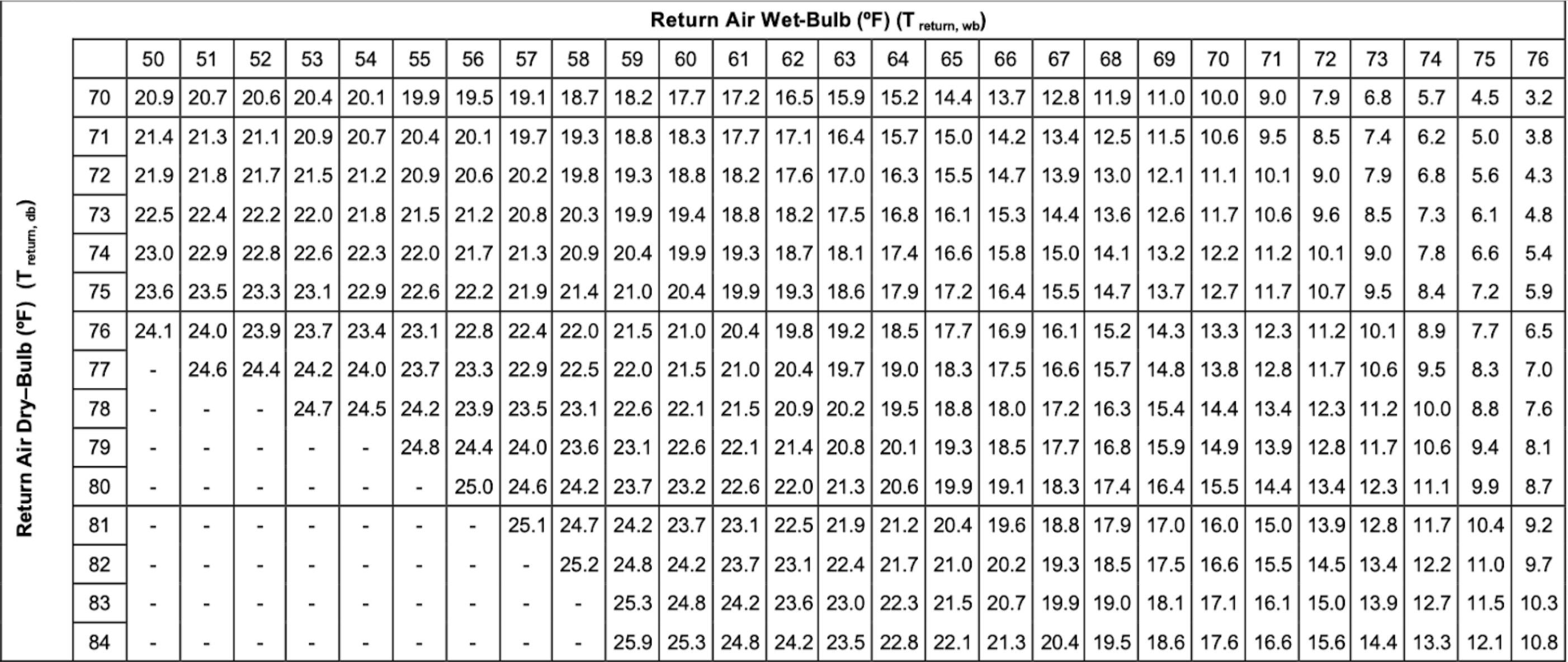

The first question you may ask is “Well, what about the humidity? That affects the target temperature split does it not?” Absolutely, for comfort cooling at or near design we are looking at a very small window, which are typical comfort conditions for most homes. ACCA manual J has a bullseye temperature of 75°DB and 50% Rh (62°WB) for a wet climate and 75°DB and 45% Rh (60°WB) for a dry climate.

This means that the target temperature split is 19.3-20.4°DB. So again, when the thermostat satisfies, the target temperature split should be very close to 19-20 °DB. When the system is equipped with an optional room temperature sensor, the actual wet bulb can be calculated, and the target temperature drop can be precisely calculated with regard to the moisture content of the air. The key thing here though is to remember that we are monitoring normal operation and looking for deviation not servicing with SmartAC.com at the fringes where things are far from standard conditions.

The temperature difference across a furnace or heat pump coil can also be monitored. In the case of a standard heat pump the temperature split tracks with the outdoor air temperature. As the outdoor air temperature decreases so does the temperature rise across the coil. At 65°DB outdoor air temperature the rise can be as high as 36°DB and at 20°DB degrees as low as 16°DB. With inverter technology, the temperature rise often tracks the return air temperature. The lower the return air temperature the higher the rise.

In the case of a furnace, temperature rise tracking is critical to prevent long term damage to the furnace heat exchanger. As the cycle time is also measured, a furnace trapping on a limit or other safety can easily be identified.

3. Water Leakage

While it may be easy to envision a water loss caused by heavy rain and winds, or a river that has overrun its banks, water damage caused by internal plumbing is often the most common, most damaging, and most unexpected type of water loss. According to industry estimates, 14,000 people in the US experience a water damage(1) emergency at home or work each day, and 98% of basements in the US will suffer from some type of water damage during their lifetime.

Air conditioners manage tremendous amounts of water. A typical residential system operating at standard design conditions will easily remove as much as 15-20 gallons/day. It’s not hard to imagine the damage that 20 gallons of water spilled on an attic ceiling, or a finished basement floor might do. Give that a week while you’re on vacation and expect to see the damage caused by 100 gallons or more.

4. Filter Pressure Drop

Filters over time load with particulates composed of dust, dirt, pet dander, hair, mold spores and even some viruses to name a few. These particulates clog the filter resulting in a restriction in the airstream. As the filter loads with dirt, depending on the type of motor in your furnace, one of two things will start to happen.

With modern furnaces equipped with an ECM motor the fan efficacy (watts/CFM) will increase reducing the overall system efficiency, but the system airflow will remain relatively close to the same. On an older system the watt draw will decrease, but the airflow will drop significantly resulting in your system becoming a giant dehumidifier. While this may seem advantageous, converting sensible capacity to latent capacity means longer run times and significant sensible cooling capacity losses.

By using a barometric pressure to sense the pressure drop during the system off cycle then comparing it to the pressure when the system is on, the filter life can be monitored by both pressure drop and time.

5. Indoor air quality (IAQ)

The room sensor is designed to measure temperature and relative humidity. The most important limiting factor for house-dust-mite populations is air humidity(2). Also, the relative humidity has been shown to have profound effects on spore and particle release from fungal structures with which surfaces are infested(3). Continuous monitoring of the air filter, temperature, and relative humidity afford the opportunity to identify and rectify potential sources of indoor air quality issues.

By simply watching a small number of system variables, SmartAC.com can determine when a billable truck roll should occur.

So, what is SmartAC.com monitoring and what can it detect?

Changes in the way that the system works!

- A gradual increase in time to satisfy the cooling or heating load at a specific outdoor air temperature indicating loss of charge or a dirty condenser

- A significant change in actual vs target temperature split at the end of the system cycle that indicates a change detrimental to performance.

- Low refrigerant charge

- High discharge air temperature in the case of a furnace or heat pump

- Dirty filters (high pressure drop)

- Short cycling in heating or cooling

- Tripping on a high- or low-pressure switch

- Tripping on a limit

- Lower than normal discharge air temperatures indicating low airflow or restricted filter or a frozen coil.

- A significant gain in the return air duct system pressure signaling a restricted/dirty filter.

- Loss of duct system pressure indicating a dirty blower, restricted coil, frozen coil, or an excessive number of closed registers.

- Loss of heating or cooling (space temperature exceeds or falls below typical)

- Water resulting from condensate drainage issues.

- Temperature and humidity conditions that could result in poor IAQ

- Duct gain or losses during an off cycle

- Data signature changes indicating a change in operation

- Moisture sensor could be installed on a window for sensing condensation (RH setting to high or relative humidity is not controlled properly)

How can SmartAC.com change the way that you are working?

It’s the best way to upgrade your maintenance agreements. Maintenance agreements are typically a loss leader for many service companies. If no other opportunity is found, they are often a break even service offering. If a callback occurs, because of something as simple as leaving a service switch off, they are simply a loss. The true purpose of maintenance agreements is to find opportunity (sell) and maintain a relationship (create stickiness) with the customer and the company with hopes that they will get a dedicated opportunity to replace the system when the time is right.

Upgrade from 2 to 1, or 1 and done!

Become the 2 to 1 Contractor. Deploy SmartAC.com measureQuick and watch the results.

- Make sure every truck roll is a billable truck roll

- Find system faults with measureQuick

- Charge for and perform the heating and cooling inspection at the same time

- If a heat pump only, service only as needed. If there is no heat exchanger, an annual visual inspection is not needed.

- Leverage your branding with automatic monthly reports.

- Check the cooling system without gauges.

- Remotely screen for opportunities.

- Reduce the potential for callbacks by 50% by eliminating a trip.

- Remote your QA/QC with measureQuick.

- Fully integrated with ServiceTitan.

- Maintain and/or improve the stickiness with customers.

Sources:

[1. https://www.waterdamagedefense.com/ ]

[2. https://www.science.gov/topicpages/h/house+dust+mites ]

[3. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3497365/ ]